Plastic Pvc Water Pipe Extrusion Mould

Brand Zhuoran Mould

Product origin huangshi

Delivery time 30-35days

Supply capacity 100 sets/month

1. Our biggest advantage is have their own mold production development workshop, we can understand customer's idea, according to the customer's idea to make the product shape and regulation performance . A one-stop service .

2. Our company has 15 years of development history, has rich experience in plastic profile extrusion, can help customers to solve problems in the production.

3. As long as you have simple drawings, or samples, we can produce finished products and moulds for you. Ten years of experience of designers.

4. Our factory has more than 10 production lines, several hundred workers , the late from the early stages of production to the finished product has strict rules.

Our extrusion mould advantages:

1. We are founded in 2012,extend 15 years professional experennce gives us dominate position in extrusion moluld industry., quality and precision are the most import target of our company.our products enjoy an excellent reputation in plastic extrusion mould industry.

2. We owned a team of mature and experienced technicians,rich experiences skill workers from design, manufacture and debugging.

3. We can make all kinds of moulds according to customer requirement.The mould can be post-co extrusion, color co extrusion, embossing co extrusion, surface layer and so on.

4. Provide complete set of production process and technology transfer service

5. Flow channel systematic design is based on theoretical calculation, practical conclusion, adopting reasonable compressing ratio and stain technology according to different formula and technique

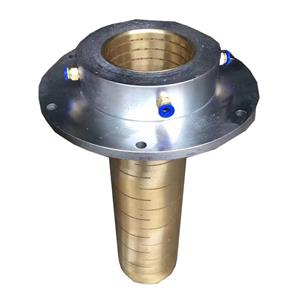

Die:

Designed by different formulations and melt flow characteristics

Multi-cavity with material supplied to each cavity respectively,Smooth of flowing channel

Integated mandrel structure, Mirror polishing

Calibrator:

High efficient and even cooling system

A number of patented brightening technology

The perfect combination of precise positioning and reliable shape

Water tank:

Spraying and immersing cooling system

Vacuum and whirling water tank

Floating tank plates, Find position automatically

Inside Feature of Our Die Head

Inside Feature of Our Die Head

1. Water cooling through mandril can cool the inner cavity thoroughly, the inner cavity could be smooth and regular, and there will be no swelling taking place. The section view of profile is very regular and good looking. (Air cooling or natural cooling will make the inner cavity liable to swell and make the inner rib uneven).

2.The water flow in the mandril can be controlled by valve, and make the products' inner cavity and outer wall cool synchronously, thus improve the inherent quality such as anti impact strength, meanwhile improve the stability of products' quality in the production.

3. The cooling efficiency outperforms air cooling and natural cooling countpart so the product extrusion speed can be improved greatly.